DIESEL TECH’S

BDS Suspension adds to its lineup of vehicle-specific mounting kits for the RECOIL traction bar system with redesigned kits specifically for the 2020+ Chevy/GMC 2500HD/3500HD trucks designed for easy bolt-on installation. Designed to improve on- and off-road performance so you can put the power to the ground, RECOIL features a full float and spring-loaded design, allowing it to perform well in multiple terrains where traditional traction bars would bind up the suspension. (517-279-2135 // www.bds-suspension.com)

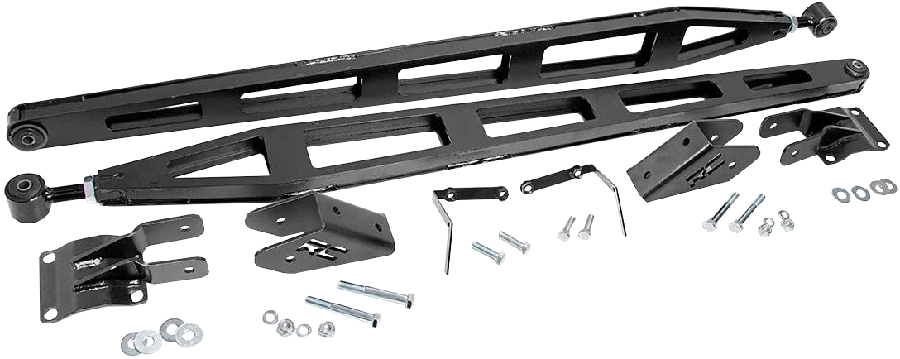

The Longhorn Fab Shop’s traction bars are a great solution and are affordable enough for the daily driver truck, yet strong enough for dedicated sled pullers and drag racers. Whether you drive your truck to watch the competition, or trailer it in because you are the competition, you’ll love the strength, design, adjustability, and ease of installation, and it fits all available axles. (855-797-8478 // www.longhornfabshop.com)

Apoc Industries

Apoc Industries are a bolt-on kit to easily enhance the look of your Ford Super Duty and also add much needed support for your rear suspension. Today’s trucks can put some serious power to the ground, causing wheel hop and leaf spring damage, stock or lifted, and your truck will benefit from a quality set of traction bars. If your truck is using lift blocks, a set of traction bars will add needed stability to your rear suspension. Apoc’s simple bolt-on kit clamps around your rear axle housing and bolts to your frame. Drilling is required for the frame mount unless you weld it on. And they’ve also added an adjustable end to allow adjustments for easier installation, or if you decide to lift your truck after installing their traction bars, you can adjust the traction bar. (865-983-5004 // www.apocindustries.com)

The biggest thing to remember with diesel trucks is that they are extremely front-end heavy. This is because of the heavy engine bays, plow setups, and systems that are common in the diesel industry. This weight imbalance over the tires combined with all the torque that is made causes more wheel hop than with ordinary vehicles. The biggest thing that the HSP Bolt-On Traction bars do is plant your suspension by taking different points of the axle and tying them into the frame, enabling efficient transfer of power while keeping the axle from moving. When the axle is secure, that power is now being effectively transferred to the road. And HSP traction bar kits have proven by drag racers, street monsters, and even everyday users that they do nothing but improve the efficiency of your truck! (586-785-3110 // www.hspdiesel.com)