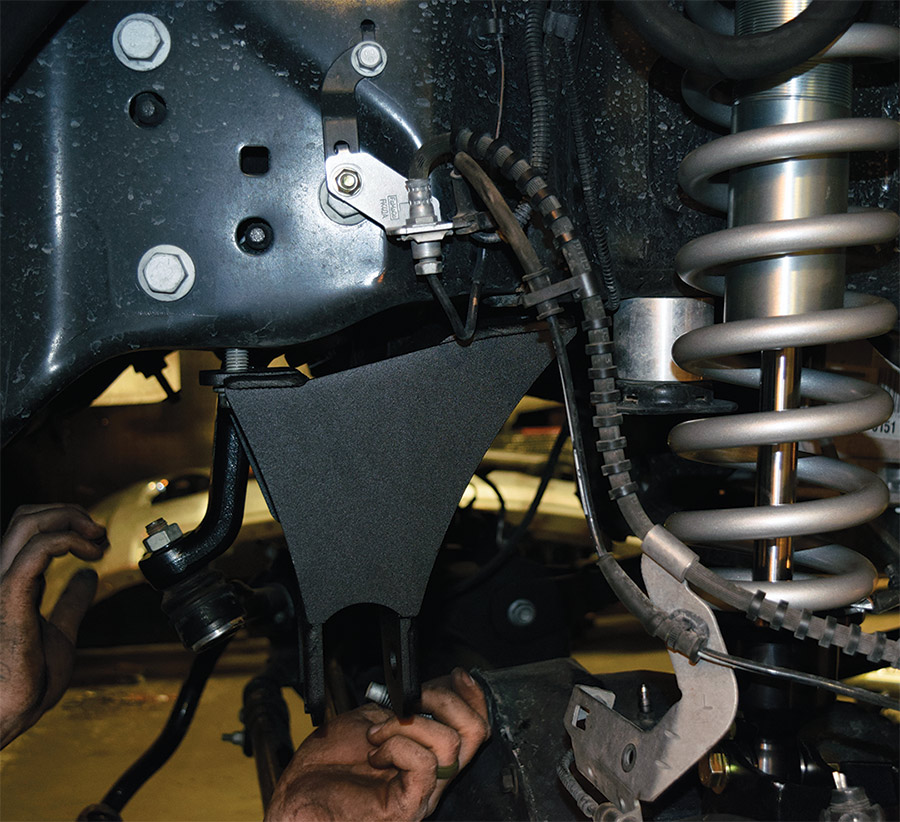

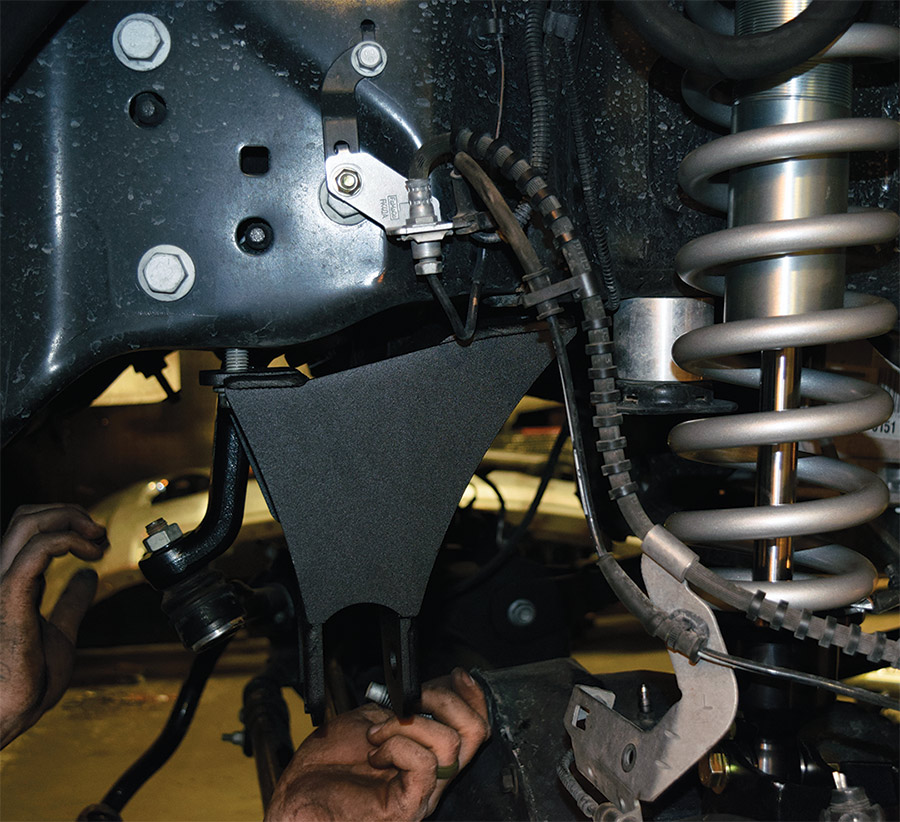

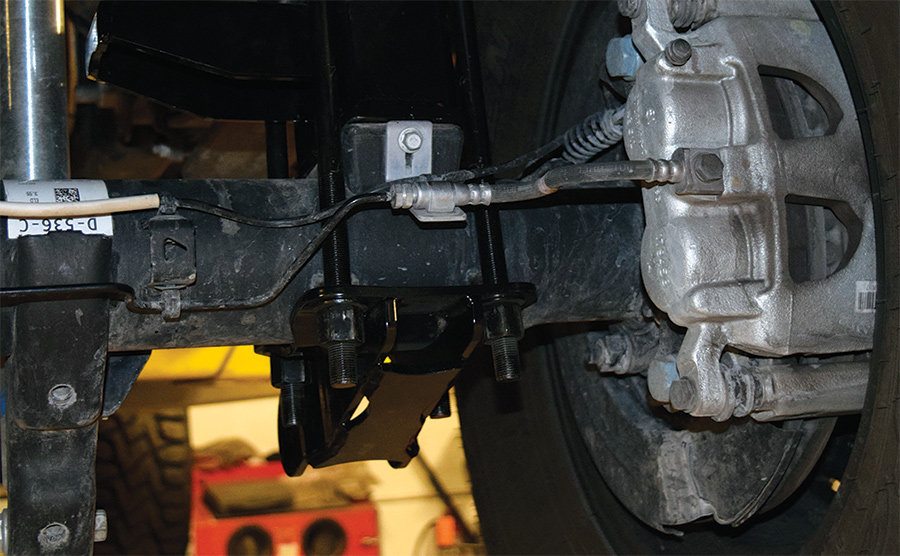

The 4-link brackets are built from 1/4-inch steel, they key off the factory frame bracket and transmission cross member for extra strength, and they utilize heavy-wall 2-inch control arms to correctly position the front axle. The included FOX coilovers also work perfectly for the heavy weight of the 6.7L Power Stroke, and FOX 2.0 IFP performance gas shocks further enhance dampening for a smooth ride on any terrain. With this kit, we’ll be ready for anything. For the installation we returned to our friends at PowerTech Diesel in Idaho Falls, Idaho, where technician Jordan Johnson did the install.

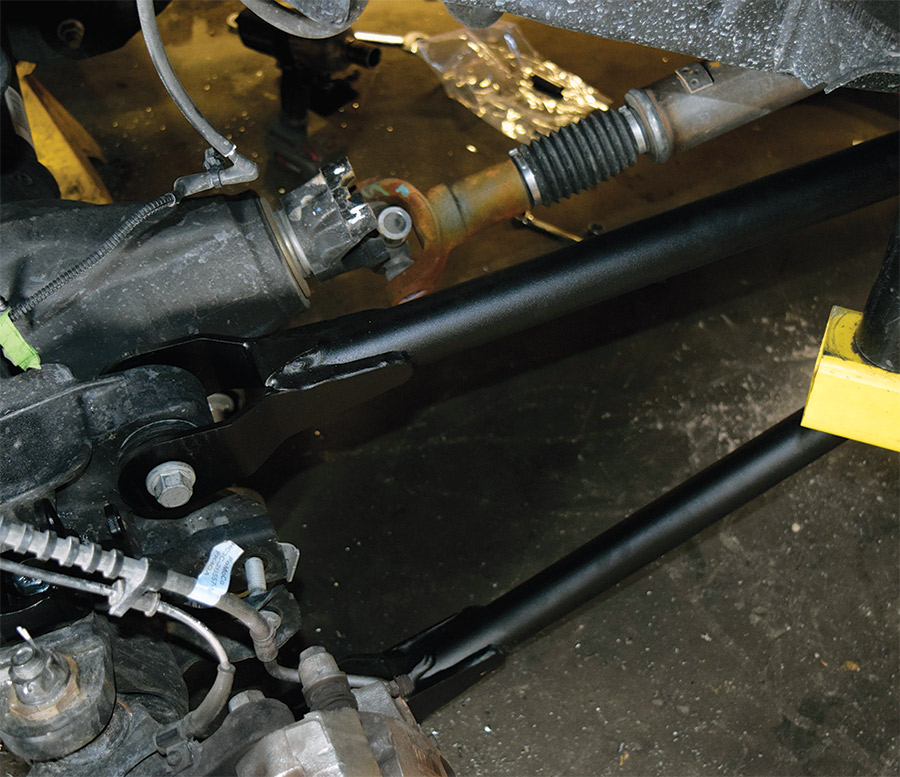

“I leave the bolts loose until all the parts are in place when I can,” says Jordan. “The parts need to establish their position and I want to leave room for error in case adjustments need to be made.” With the new arm in place, he uncoupled the drive shaft from the axle before continuing radius arm work, as it would get in the way. Next, he bolted in one of the lower (long) arms on the driver side. This process was repeated on the passenger side.

“I leave the bolts loose until all the parts are in place when I can,” says Jordan. “The parts need to establish their position and I want to leave room for error in case adjustments need to be made.” With the new arm in place, he uncoupled the drive shaft from the axle before continuing radius arm work, as it would get in the way. Next, he bolted in one of the lower (long) arms on the driver side. This process was repeated on the passenger side.